Available for Import

Available for Import

Horizontal Machining Center STC N 125M for High-Speed Processing

Manufacturer:

ISZ LLC

Price:

Request Quote

Bulk pricing available

FOB, CIF & EXW terms available

Description

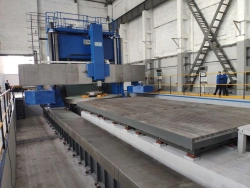

Horizontal milling machining centre model STC H 125M (IS1250PMF4) is designed for high-speed machining of complex surfaces of large-sized parts made of cast iron, steel, aluminium and other metals. The machines are equipped with preloaded roller guideways providing the speed of movement of units up to 15 m/min.

The machine is made on the basis of the machine model IR1250, with a deep elaboration of nodes, with the following design changes: increasing the rigidity of base parts, equipping the machine with spiral conveyors of chips on the X and W axes, the use of double-slope telescopic protection on the W axis, the construction of a new stationary fence of cabinet type, which allowed to improve the tray system of leakage collection and provide a guaranteed sealing of the cutting zone.

The machine is made on the basis of the machine model IR1250, with a deep elaboration of nodes, with the following design changes: increasing the rigidity of base parts, equipping the machine with spiral conveyors of chips on the X and W axes, the use of double-slope telescopic protection on the W axis, the construction of a new stationary fence of cabinet type, which allowed to improve the tray system of leakage collection and provide a guaranteed sealing of the cutting zone.

Specifications

Type of product according to PP RF 616

5-axis horizontal machining centers

Length

7200 mm

Width

5500 mm

Height

4300 mm

Machine type

Machining centre STC H 125M

Maximum spindle speed 2250, 2500*, 3000

2250; 2500*; 3000

Diameter of boring spindle

110; 130* mm

Maximum table torque in the B axis

5000 nm

Working feed rate limits of the rotary table in the B axis

1 .... 1080 deg/min

Table load capacity, kg

6 000 kg

Table work surface size

1100?1250; 1250?1250; 1250?1500; 1250?1400*;1400?1600; 1600?1800; 1600?2000 mm

Machine weight

20000 kg

Overall dimensions (width/length/height)

5 200 / 6 500 / 4 300 mm

Coolant supply via nozzles on the spindle headstock,

100 l/min l

Positioning repeatability accuracy

0;0025 mm

Axis positioning accuracy

0;005 mm

Maximum tool length,

400 mm

Maximum tool diameter

125 mm

Capacity of instrument magazine, pcs.

SBVVBG pcs

Maximum feed force in the X/Y/Z/W axes,

kn 12;5 / 10 / 10 / 10 / 15

Rapid Travelling Speed in X, Y, Z, W axes m/min 15

m/min 15 mm

Working feed rate limits in X, Y, Z, W axes

1 .... 15000 mm/min mm

Maximum programmable movements,

mm: - x-axis (table transversely) 2000 - y-axis (spindle headstock vertically) 1220*; 16001) - z-axis (boring spindle) 710 - w-axis (stand longitudinally) 1600 mm

Maximum torque on the spindle,

1700*; 2500 nm

Rated power of the spindle rotation drive

28 kW

Note: All specifications are provided by the manufacturer and may be subject to change. Please contact us to confirm the latest specifications before placing your order.

Share your requirements for a quick response!

Instant response in 15 minutes

Best wholesale prices guaranteed

Direct from manufacturer

Delivery & Payment

Shipping Terms

Delivery Time

Sea freight: 30-60 days (depending on destination)

Air freight: 14-21 days (for urgent orders)

Payment Methods

Similar Products You May Be Interested In

4-Axis Machining Center MC-200 with Horizontal Spindle for Parts 200x200x200 mm

View Details

Semi-Automatic Two-Support Chuck Center Lathe 1A740RF3

View Details

VC40 Gantry Machine - Precision Machining Center

View Details

5-Axis Portal Milling Processing Center SK6P300 CNC Model 4/1.25/L1

View Details

CNC Vertical Milling Machine Center PLOT VGI-322

View Details

VMB 800 Machining Center for Comprehensive Milling Processing

View Details

High-Speed Horizontal Machining Center Super Center IS630

View Details

Five-Axis CNC Vertical Machining Center for Metal Processing BEAVERMILL BVR.B-130

View Details

Five-Axis Portal Milling Machine Center SK6P250 CNC 32/1.25/L1

View Details

Vertical Milling Machining Center TSZF1370

View Details

SK6P Portal-Type Machining Center and Modifications

View Details

Vertical CNC Milling Machine FS-1000

View DetailsVerified Suppliers

All products are sourced directly from authorized Russian manufacturers

Quality Assurance

Products meet international quality standards with proper certification

Global Shipping

Reliable logistics solutions to deliver products to your location

Secure Payments

Multiple secure payment options to facilitate international transactions