Russian Thermal Processing Units Products

Featured Products

Purified Water Storage Tank

Bitumen Emulsion Preparation Unit Bastion EU-5

Automatic Welding Machine for Longitudinal and Circular Joints

Biotechno CIP Station - Automated Cleaning for Fermenters & Reactors

Washing Bath for Mine Applications, Model VShP

Electric Cleaning Bath for Parts - Model VP

Thermal Destruction Units, Model UTD

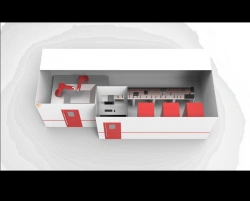

Automated Ion-Plasma Coating System MAP-2M

Normalization Bath for High-Fat Creams VN Series

Hot Washing Bath Model VGP-1 for Part Neutralization

Gasification Systems ARIA for Liquefied Gases

High-Density Coating Application System NIKA-151

Friction Welding Machine PST-50C for Bi-metallic Connectors

Laser Shock Peening System with Pulse Energy from 1 to 50 Joules

Oil Bath for Shaft, Model VShM

Pre-Paint Preparation Equipment INSTALIKA LIMA

Optimal Climate Drying Chamber INSTALIKA ALFA

Automated Coating System "MAP-2" for Ion-Plasma Coatings

Autoclave System AYT-2000-12800-10-EV for PKM Molding

Biotechno Separation Module with Piping for Liquid Filtration

Electric Wash Bath for Cleaning Parts - Model VShP

Friction Welding Machine PST-20T for Drill Pipe Production

Water Quenching Tank for Hardening Parts - BZV

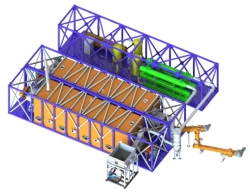

Automated Thermal Gas-Phase Vacuum Installation UATGV

INSTALIKA PROFI Paint and Drying Chamber

High-Density Coating System KN-9

Heat Treatment Bath, Model VZ

Autoclave Installation UAGV-G-3.0-4.0-1.2 for Pressure Treatment

IRS Technical Complexes for Material Processing with Temperature Change

Capacitive Mixing Apparatus with Mechanical Agitation AEMP Series

Bitumen Emulsion Preparation Unit BASTION EU-10

Kepler Vacuum Coating System for Large-Scale Applications

Saha Vacuum Coating System

Electric Tempering Bath for Cooling in Liquid Medium, Model VZ

Bitumen Emulsion Preparation Unit BASTION EU-1

Oil Quenching Bath, Model VZM

Oil Cooling Bath for Shaft, Model VShM

Biotechno Filtration Systems with Ceramic Membranes

Portable Gas-Oxygen Cutting Machines for Pipes GAKS-R (Track, Krot)

Friction Welding Machine PST-80T for Trailer Axle Manufacturing

Polymer Waste Recycling Granulator

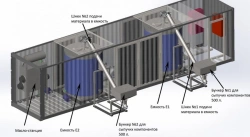

Gas Heating Unit (BPG) "ISTOK

Electric Tempering Bath Model VShZ for Cooling Applications

Modified Bitumen and Bitumen Mastic Preparation System PG Bastion UPMBiBM

Oil Bath Model VM for Precise Temperature Control

Vertical Fermentation Vessel for Liquid Food Storage - ESV Series

Biotechno Bioreactors (3000 to 10000 liters)

Water Tempering Bath, Model VZV

Electric Air Thermostat AT-1 for Temperature Control

About Thermal Processing Units

Welcome to our comprehensive range of Thermal Processing Units, designed to meet the diverse needs of businesses across Africa, the Middle East, and South Asia. These units are essential in industries where precise temperature control and processing are critical. Our products help solve operational challenges by ensuring efficient heating, sterilization, and material processing, making them indispensable for improving production efficiency and product quality.

Applications and Users

- Food and Beverage Industry: Our units like the Universal Tank of EUV / EUG series are perfect for storing, fermenting, and processing liquid food products. They maintain optimal temperatures, ensuring high-quality outputs.

- Pharmaceuticals and Biotechnology: Equipment such as the Biorus® fermenters are ideal for cultivating bacteria, fungi, and cells, which are crucial for drug development and research labs.

- Manufacturing and Industrial Processing: Products like the Autoclaves with quick release lids and Oil quenching baths are vital for material synthesis and treatment processes, enhancing product durability and performance.

- Construction and Material Science: The Autoclaves, types "AB", "AP", "AT" are used for vulcanizing rubber and polymerizing composites, essential in construction material manufacturing.

Technical Characteristics

- Capacity: Varies from small-scale units to large industrial setups (e.g., fermenters from 50 to 15,000 liters).

- Temperature Range: Our units operate across a broad spectrum, with some reaching up to 450°C.

- Materials: Constructed from durable materials like stainless steel, ensuring longevity and reliability even in harsh conditions.

- Pressure: Autoclaves and other units handle pressures up to 4.0 MPa, suitable for demanding industrial applications.

Why Choose Our Thermal Processing Units?

- Adaptability: Suitable for various industries, from food processing to pharmaceuticals and heavy manufacturing.

- Cost-Effective: Russian-made products offer excellent value, combining affordability with robust construction, making them a competitive choice over European counterparts.

- Durability: Designed to withstand challenging environments, these units are reliable under continuous operation, reducing downtime and maintenance costs.

- Business Growth: Importing these units can enhance your service offerings, allowing you to cater to more clients or expand your production capabilities.

Explore our Thermal Processing Units to find the right solutions for your business needs. Whether you're looking to buy, import, or seek competitive prices, our products are tailored to support your growth and operational efficiency.

Frequently Asked Questions

To order products from Russia through our platform, select the product you're interested in, click the "Request Quote" button, and fill out the request form. Our managers will contact you to clarify the details and provide a commercial proposal.

We offer various payment methods, including prepayment, partial payment, irrevocable letter of credit, and other options. Payment terms are discussed individually for each deal and depend on the order volume, delivery country, and supplier requirements.

We deliver Russian products to any point in the world. Our company has well-developed logistics routes and partnership relationships with transport companies, which allows us to organize delivery as efficiently as possible.

Yes, we work with requests for supply of products that are not in our catalog. Send us a technical assignment or describe the required product, and we'll find a suitable manufacturer in Russia.