Available for Import

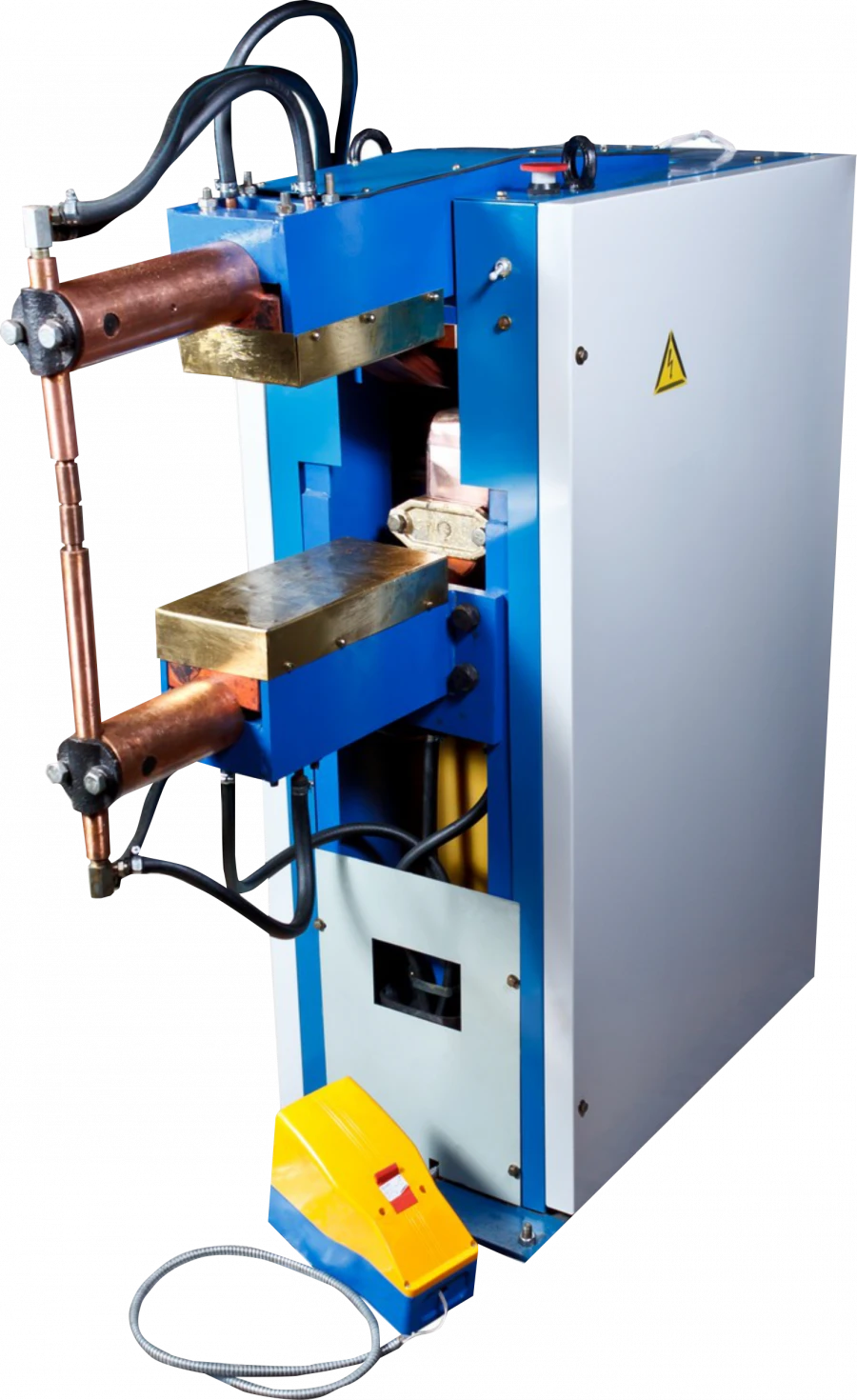

Available for ImportContact Welding Machine MTR-1701 UHL4 for Low-Carbon Steel Applications

Bulk pricing available

FOB, CIF & EXW terms available

Description

Contact welding machines are designed for electric contact spot welding of parts made of low-carbon steel sheets, for overlap welding of reinforcement of II and III class. The machines are designed for operation in the following conditions: ambient temperature from plus 1°C to plus 35°C, ambient humidity up to 80% at 25°C, atmospheric pressure from 84.0 kPa (630 mm Hg) to 106.7 kPa (800 mm Hg); cooling water temperature from plus 5°C to plus 25°C. Climatic version UHL - operation of machines in macroclimatic regions with temperate and cold climate. Category 4 provides for the operation of machines in closed heated (cooled) and ventilated rooms.

Specifications

Note: All specifications are provided by the manufacturer and may be subject to change. Please contact us to confirm the latest specifications before placing your order.

Share your requirements for a quick response!

Delivery & Payment

Shipping Terms

Delivery Time

Payment Methods

Similar Products You May Be Interested In

Reliable Contact Welding Machine MTR-2401 UHL4

View Details

Welding Generator ADD - 2x2502 I U1

View Details

Automatic Welding Machine ADF-1002-2 U3

View Details

Welding Machine ADB - 2x2502 PR and U1

View Details

Welding Machine ADD-4004 PR and U1

View Details

Welding Generator GD-4004 U2 Type 27

View Details

Welding Rectifier VD-306 I U3

View Details

Large Size Thermostatic Table NP 34-24 PRO with Temperature Regulator TP 2-10 KD PRO

View Details

Welding Machine ADD - 4009 I U1

View Details

Contact Welding Machine MSh-2203 UHL4

View Details

Welding Power Supply Unit ADD-5001.1 I U1

View Details

ADD-4009 I U1 Welding Machine with Electronic Panel

View DetailsVerified Suppliers

All products are sourced directly from authorized Russian manufacturers

Quality Assurance

Products meet international quality standards with proper certification

Global Shipping

Reliable logistics solutions to deliver products to your location

Secure Payments

Multiple secure payment options to facilitate international transactions