Available for Import

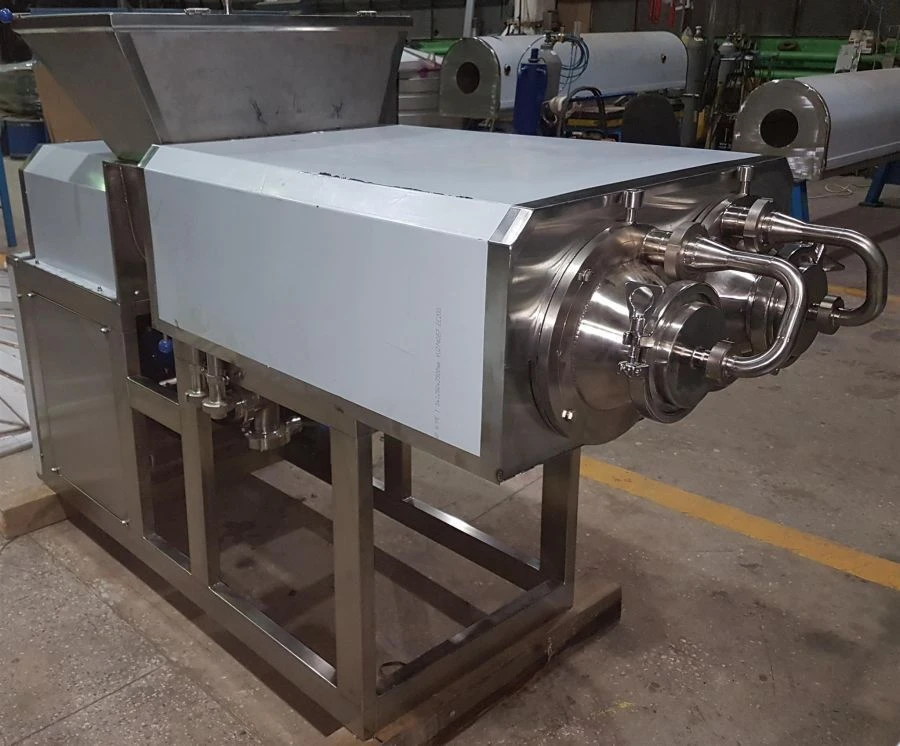

Available for ImportContinuous Curd Cooler OT-1000-2SH for Efficient Curd Processing

Bulk pricing available

FOB, CIF & EXW terms available

Description

Cheese curd cooler screw brand OT, hereinafter cooler, is designed for continuous cooling of curd with separated whey (GOST R 52096-2003), fed into the hopper cooler. Technical capacity 780 kg/h Cooling surface-3,7m2 Rotational speed of displacing drums-0,49 Curd temperature, ° C, not more than at the inlet to the cooler32-36 ° C at the cooler outlet 12-16 °? Refrigerant-water Refrigerant temperature at the cooler inlet not more than 1 °? Refrigerant pressure not more than 0,3 MPa Refrigerant flow rate not less than-9m3/h Electricity consumption not more than -6kWh Washing solution pressure0,2...0,3, MPa Overall dimensions of the cooler, mm, not more: Length-2500 width-1000 height (without hopper)-1300 Cooler weight not more than 700 kg Overall dimensions of two stands under augers, mm, not more: length1400 width-800 height1100 Weight of two auger stands is not more than 80 kg. Warranty period of operation - 12 months from the date of commissioning of the cooler...

Specifications

Share your requirements for a quick response!

Delivery & Payment

Shipping Terms

Delivery Time

Payment Methods

Similar Products You May Be Interested In

High-Efficiency Milk Bacteriological Separator ROTOR-OBTsP-5

View Details

Cheese Maker 300 Liters with Electric Heating and Panel Jacket

View Details

Continuous Whey Separator Model OSBT-1000 for Cheese Production

View Details

Curd Bath TV-1500 - Essential for Traditional Cheese Production

View Details

Milk Separator Cleaner Rotor-OHCP-3

View Details

Steritank for Milk and Dairy Products Model ST-300

View Details

Long Pasteurization Bath for Milk and Cream, Model VDP-150

View Details

High-Fat Cream Normalization Tanks, Type VN and Modifications

View Details

Intermediate Storage Tank for Liquids and Mixtures Model 350

View Details

Storage Tanks for Milk and Dairy Products - OSV Type

View Details

Milk Storage Tanks and Modifications for Dairy Production

View Details

Tube Heat Exchanger for Thermal Processing of Liquid Food Products VГ

View DetailsVerified Suppliers

All products are sourced directly from authorized Russian manufacturers

Quality Assurance

Products meet international quality standards with proper certification

Global Shipping

Reliable logistics solutions to deliver products to your location

Secure Payments

Multiple secure payment options to facilitate international transactions