Available for Import

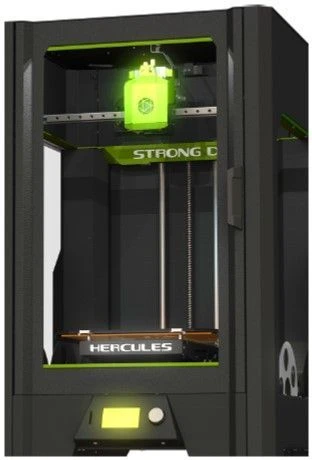

Available for ImportHercules Strong Duo 3D Printer for Dual Material Printing

Bulk pricing available

FOB, CIF & EXW terms available

Description

3D printer with 300300400 working chamber equipped with two extruders with the ability to print 2 different materials simultaneously with inactive nozzle extrusion protection and high switching speeds The developed "TwinHot" hotend with two extruders, design solution of the working chamber and Hercules control board and Hercules power board provide high speed of printing products with two materials (up to 50 cc per hour) and works with standard and flexible materials (ABS, PLA, POM, PVA, HIPS, PETG, FLEX, PP, RUBBER, CARBON, ETERNAL, SBS, PC-ABS, NYLON, WOOD). The developed systems of plastic control "Sensitive check", nozzle calibration "NBN System", "Stand by", unique automatic calibration (platform and zero point calibration) and a comprehensive light indication system automate the work with the 3D printer and allow to reduce the requirements to the user of the equipment Allows printing with nozzles with diameters from 0.2 to 1.2 mm and layer thicknesses from 20 to 900 µm

Specifications

Note: All specifications are provided by the manufacturer and may be subject to change. Please contact us to confirm the latest specifications before placing your order.

Share your requirements for a quick response!

Delivery & Payment

Shipping Terms

Delivery Time

Payment Methods

Similar Products You May Be Interested In

Professional 3D Printer with Large Print Area - PICASO 3D Designer XL PRO S2

View Details

F2 Pro Pellet Industrial Granule 3D Printer

View Details

3D Printing System with Three Printers RF1

View Details

5-Axis 3D Printer Stereotech HYBRID 530

View Details

Additive Manufacturing System "Larets" SM-A284 3D Printer

View Details

Industrial High-Temperature 3D Printer F2 Quart Pellet

View Details

Affordable 3D Printer for Professional Tasks - PICASO 3D Designer Classic

View Details

Total Z AnyForm 250-SLS 3D Printer

View Details

Compact 3D Printer with Dual Extruders ALKINOID

View Details

Total Z MPC-310 Post-Processing Chamber

View Details

Helios-1 BG-91 3D Printer for Precision Printing

View Details

Industrial 3D Printer F2 Quart

View DetailsVerified Suppliers

All products are sourced directly from authorized Russian manufacturers

Quality Assurance

Products meet international quality standards with proper certification

Global Shipping

Reliable logistics solutions to deliver products to your location

Secure Payments

Multiple secure payment options to facilitate international transactions