Available for Import

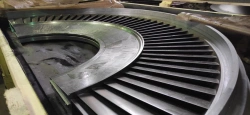

Available for ImportHigh-Pressure Turbine Cylinder Assembly for T-100-130 Upgrade Applications

Manufacturer:UTZ OJSC

Price:Request Quote

Bulk pricing available

FOB, CIF & EXW terms available

Description

The project of modernisation of turbine T-100-130 provides for replacement of units and parts of the turbine operating at high temperatures and exhausted resource, and includes types of works - replacement of:

- complete DDC and CSD with installation on the existing foundation and new housings of the front bearing block and middle (thrust bearing) bearing

- control and locking valves

- cam-type distributor of the UA control valves

- CND flow section

- control diaphragm servomotor

- foundation frames under the housings of the front bearing block and the centre (thrust) bearing block

- two safety valves on the lower heating extraction pipeline for one safety valve

- organisation of additional steam extraction behind the CVD from the bypass pipe of the CVD-CSD to the general station collector with a flow rate of up to 70 t/h.

Designation of the turbine after Modernisation: T-110/120-12,8 PR2.

- complete DDC and CSD with installation on the existing foundation and new housings of the front bearing block and middle (thrust bearing) bearing

- control and locking valves

- cam-type distributor of the UA control valves

- CND flow section

- control diaphragm servomotor

- foundation frames under the housings of the front bearing block and the centre (thrust) bearing block

- two safety valves on the lower heating extraction pipeline for one safety valve

- organisation of additional steam extraction behind the CVD from the bypass pipe of the CVD-CSD to the general station collector with a flow rate of up to 70 t/h.

Designation of the turbine after Modernisation: T-110/120-12,8 PR2.

Specifications

Minimum scope of modernization

modernisation of t-100 series turbine replace resource nodes and parts; operating at temperature more than 450°c. it allows to renew resource; and also to increase nominal; maximum power and heat load in condensing mode.

Average volume of modernization

In addition to the replacement of high-pressure and medium-pressure cylinder resource units and parts; additionally includes the replacement of low-pressure flow section; and by-pass tubes from high-pressure cylinder to medium-pressure cylinder.

Maximum scope of modernization

in addition to the medium variant, the low-pressure flow part is replaced; this allows to increase the reliability of the low-pressure part operation

Share your requirements for a quick response!

Instant response in 15 minutes

Best wholesale prices guaranteed

Direct from manufacturer

Delivery & Payment

Shipping Terms

Delivery Time

Sea freight: 30-60 days (depending on destination) Air freight: 14-21 days (for urgent orders)

Payment Methods

Similar Products You May Be Interested In

Left Guide Blade for 30 Steps 47T230-3243

View Details

Turbine Upgrade Kit for T-100/120-130-2 Model

View Details

Medium Pressure Cylinder (CSD) with Valve Block SD for K-800-23.5-5MR Steam Turbine

View Details

Low Pressure Cylinder Rotor CND Drawing 48T230-3275CBR

View Details

Rear Bearing PS.100.314.00.000 for Turbines

View Details

CND Turbine First Stage Diaphragm T-96/110-90

View Details

Medium Pressure Cylinder (CSD) with Valve Block for K-330-23.5-6MR Steam Turbine

View Details

Diaphragm for Steam Turbine Cylinder Separation 47T230-3218

View Details

Steam Turbine Upgrade Kit K-215-130-1M3 for CND Block #9

View Details

Medium Pressure Cylinder (CSD) with SD Valve Block for K-330-23.5-8MR Steam Turbine

View Details

Special Check Valve KOS 150-1M10 for Turbine Protection

View Details

Steam Turbine Coupling PS 200.1411580

View DetailsVerified Suppliers

All products are sourced directly from authorized Russian manufacturers

Quality Assurance

Products meet international quality standards with proper certification

Global Shipping

Reliable logistics solutions to deliver products to your location

Secure Payments

Multiple secure payment options to facilitate international transactions