Available for Import

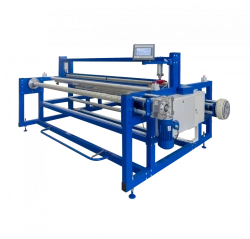

Available for ImportMaterial Unwinding Machine C01.1 for Efficient Unrolling and Rewinding

Bulk pricing available

FOB, CIF & EXW terms available

Description

Machine rewinding machine for unfolding material model C01.1 is designed for unfolding the material, folded in half and wound into a roll, and twisting it into a roll. The machine provides rewinding of material up to 600 mm in diameter and weighing up to 90 kg into rolls on a cardboard sleeve. It is available in widths up to 2500 mm, up to 3200 mm and up to 3500 mm. The machine is equipped as standard with automatic edge levelling of the finished roll, electronic metre counter MK1 Touch Rolltex, two spreading rollers for smoothing the material across the width, roll end stop sensor, etc. Additionally, it can be equipped with a viewing screen with lower illumination, additional upper illumination, manual or automatic cut-off knife, roll density adjustment system, Astra software for accounting of unwound materials, weighing system for winding the roll, adjustment of the illumination width.

Specifications

Note: All specifications are provided by the manufacturer and may be subject to change. Please contact us to confirm the latest specifications before placing your order.

Share your requirements for a quick response!

Delivery & Payment

Shipping Terms

Delivery Time

Payment Methods

Similar Products You May Be Interested In

VK-2250 Calender Ironing Machine for Drying and Ironing

View Details

Non-Woven Material Rewinding Machine Model B01.23

View Details

Measuring and Rejection Machine A02.1

View Details

Measuring and Reeling Machine Model B01.46

View Details

Smooth Ironing Roller VГ-2030

View Details

Measuring and Rewinding Machine A02.5

View Details

Quality Control and Measuring Machine Model B02.14

View Details

VK-1840 Calender Ironing Machine for Efficient Drying and Ironing

View Details

Measuring and Defect Inspection Machine B02.4 for Elastic and Non-Elastic Materials

View Details

Non-Woven Material Rewinding Machine B01.21

View Details

Measuring and Winding Machine Model C02.2 for Nonwoven Materials

View Details

Fabric Laying Trolley A01.10

View DetailsVerified Suppliers

All products are sourced directly from authorized Russian manufacturers

Quality Assurance

Products meet international quality standards with proper certification

Global Shipping

Reliable logistics solutions to deliver products to your location

Secure Payments

Multiple secure payment options to facilitate international transactions