Available for Import

Available for Import

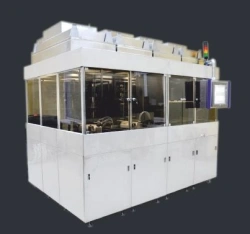

Oratoria 9-1 Vacuum Coating System for Advanced Thin Film Applications

Manufacturer:

KVARZ OJSC

Price:

Request Quote

Bulk pricing available

FOB, CIF & EXW terms available

Description

Oratorium 9-1 vacuum deposition machine

Automated installation "Oratoria 9-1" electron-beam deposition of multilayer thin films of metals, alloys and dielectrics on ceramic and silicon wafers.

The main technological characteristics of the unit are:

-Size of ceramic wafers, mm - 60x48;

-Size of silicon wafers with diameter, mm - 100;

-Number of wafers on the planetary carousel, pcs - 4;

-Number of wafers on the spherical carousel, pcs - 40;

-Number of electron-beam evaporators, pcs - 2;

-Range of substrates heating temperature - 20-400 degrees Celsius;

-Rotation of the carousel is discrete (angle of discretion 90 degrees).

The unit provides:

-Heating of substrates up to the set temperature, control and maintenance of temperature in the process of layer sputtering;

-Automatic execution of the cycle of pumping the working chamber from the atmosphere to the specified vacuum;

-Control and automatic termination of film sputtering according to the set time or the set film thickness...

Automated installation "Oratoria 9-1" electron-beam deposition of multilayer thin films of metals, alloys and dielectrics on ceramic and silicon wafers.

The main technological characteristics of the unit are:

-Size of ceramic wafers, mm - 60x48;

-Size of silicon wafers with diameter, mm - 100;

-Number of wafers on the planetary carousel, pcs - 4;

-Number of wafers on the spherical carousel, pcs - 40;

-Number of electron-beam evaporators, pcs - 2;

-Range of substrates heating temperature - 20-400 degrees Celsius;

-Rotation of the carousel is discrete (angle of discretion 90 degrees).

The unit provides:

-Heating of substrates up to the set temperature, control and maintenance of temperature in the process of layer sputtering;

-Automatic execution of the cycle of pumping the working chamber from the atmosphere to the specified vacuum;

-Control and automatic termination of film sputtering according to the set time or the set film thickness...

Specifications

Width

3650 mm

Length

3500 mm

Share your requirements for a quick response!

Instant response in 15 minutes

Best wholesale prices guaranteed

Direct from manufacturer

Delivery & Payment

Shipping Terms

Delivery Time

Sea freight: 30-60 days (depending on destination)

Air freight: 14-21 days (for urgent orders)

Payment Methods

Similar Products You May Be Interested In

Reactive Ion Etching Vacuum System with Load Lock PLASMA TM 7

View Details

Plasma-Chemical Deposition Vacuum System with ICP Source - Izofaz TM 200-01

View Details

Vacuum Coating System for Metallic Films Oratoria 29M

View Details

Vacuum Coating System UHN-74P-3M-3 for Metal Film Deposition

View Details

Vacuum Coating System with Magnetron Sputtering and Cassette Loading MAGNA TM 29

View Details

Four-Position Vacuum Coating System with Magnetron Sputtering and Electron Beam Evaporation, Model: 4P-VAC-2023

View Details

Plasma Chemical Etching Vacuum System with ICP Source and Cassette Loading TM 300

View Details

Photolithography Cluster Line - Advanced Processing Modules

View Details

Compact Plasma Cleaning Vacuum System for Photoresist Removal and Sterilization TM 4

View Details

Vacuum Coating System UHN-74P-3M-1 for Metal Film Application

View Details

Solder Paste Melting Oven with Ethernet Control - Raduga 11

View Details

Compact Vacuum Coating System for Magnetron Sputtering, Model MVU Magna 12

View DetailsVerified Suppliers

All products are sourced directly from authorized Russian manufacturers

Quality Assurance

Products meet international quality standards with proper certification

Global Shipping

Reliable logistics solutions to deliver products to your location

Secure Payments

Multiple secure payment options to facilitate international transactions