Available for Import

Available for Import

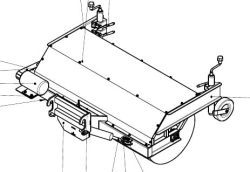

Pneumatic Spray Patching Machine Madpatcher for Urban and Highway Repairs

Manufacturer:

MADPRO LLC

Price:

Request Quote

Bulk pricing available

FOB, CIF & EXW terms available

Description

Applied on urban roads and motorways. The jet-injection method (repair with emulsion and crushed stone) has proved itself for many years all over the world

Specifications

Purpose

Road patching by jet-injection method with a mixture of crushed stone and bitumen emulsion.

Maximum capacity of ready mix equipment per hour, m³.

2

Dimensions - length

4250 mm

Dimensions - width

2290 mm

Dimensions - height

2100 mm

Weight

3200 kg

Engine type

Diesel

Engine cooling

Liquid

Number of engine cylinders

3...4 pcs

Motor power

25...40 hp

Fuel tank capacity

40 l

Computer control

availability

Location of the fuel tank filler neck

Rear (on the operator boom side)

Blower drive

Two V-belts from the engine

Emulsion flow adjustment with emulsion feed pump

stepless

Maximum blower pressure mbar.

800

Maximum blower capacity m3/min.

10.3

Maximum capacity of the emulsion pump, l/min.

5.7

The following processes can be electronically controlled from the operator panel

Emulsion pump on/off, emulsion pump capacity adjustment, internal combustion engine speed adjustment, auger speed adjustment, auger stop, engine economy mode on, audible alarm

Placement of the operator panel

On the boom

Raising and lowering the operator boom

??????????????

Positioning of the operator boom

rear

Boom swing angle

240

Feed hose length

4 m

Feed hose diameter

80 mm

Sleeve material

Reinforced PVC plastic

Number of crushed stone hopper compartments

1 pcs

Crushed stone hopper compartment volume

6.5

Crushed stone hopper awning

availability

Enclosed compartment for transportation and storage of equipment

availability

Emulsion tank volume

1300 l

Emulsion tank insulation

mineral wool

Emulsion level indicator

availability

Emulsion tank filler neck location

Rear (on the operator boom side)

Gas burner for initial heating of emulsion

availability

Heat exchanger for permanent emulsion heating, utilizing heat from the engine coolant while the engine is running

availability

Tank capacity for flushing and preserving the emulsion system

40 l

Location of the cleaning system tank filler neck

Rear (on the operator boom side)

Number of augers metering crushed stone

1 pcs

Screw drive

Hydraulic

Screw speed adjustment

stepless

Operating instructions and spare parts catalog in Russian in hard copy and electronic format

availability

Mounting kit for installation of pit repairer in dump truck body

Subframe; plates against lateral displacement, not less than 2 pcs.; ladders for fastening in assembly, not less than 6 pcs.

Note: All specifications are provided by the manufacturer and may be subject to change. Please contact us to confirm the latest specifications before placing your order.

Share your requirements for a quick response!

Instant response in 15 minutes

Best wholesale prices guaranteed

Direct from manufacturer

Delivery & Payment

Shipping Terms

Delivery Time

Sea freight: 30-60 days (depending on destination)

Air freight: 14-21 days (for urgent orders)

Payment Methods

Similar Products You May Be Interested In

Municipal Road Brush for APIS Electro Vehicle

View Details

3-Tier Aluminum Shelf Trolley for Efficient Transport

View Details

Low-Pressure Tire All-Terrain Vehicle "SHERP N

View Details

TOSS AS-3600 Sports Lawn Care Brush

View Details

Aluminum Wardrobe Trolley with 3 Shelves

View Details

Street Cleaning Brush Equipment - MKЩ Model

View Details

Mobile Communication Unit for Robotics Complex Model 5027B1-RK based on PAZ Vector NEXT

View Details

Mechanical Communal Brush for Tractors

View Details

Street Cleaning Brush with Watering System – Municipal Equipment

View Details

Modified Communication Node Model 5027G1-M Based on Gazelle NEXT

View Details

Single-Bucket Cleaning Trolley for Efficient Facility Maintenance

View Details

Dish Drying Trolley for Food Industry - TST Model

View DetailsVerified Suppliers

All products are sourced directly from authorized Russian manufacturers

Quality Assurance

Products meet international quality standards with proper certification

Global Shipping

Reliable logistics solutions to deliver products to your location

Secure Payments

Multiple secure payment options to facilitate international transactions