Available for Import

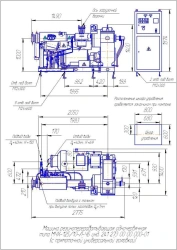

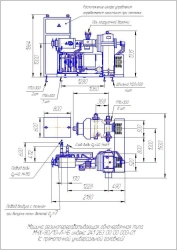

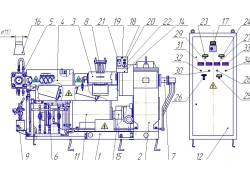

Available for ImportSingle-Screw Rubber Processing Machine MCHX-32/10-P-CHB for Extrusion Applications

Bulk pricing available

FOB, CIF & EXW terms available

Description

Designed for processing rubber mixtures by extrusion method (syringing) through the forming elements of the heads. Rubber processing machine single worm, cold feeding (the temperature of the mixture when entering the feed hopper no more than 15 ... 30 ° C), with a worm diameter of 32 mm, the ratio of the working length of the worm to its diameter (L / D) = 10, productivity 32 ...

28 kg / h, with the right-hand side location of the service area in the course of the profile, asynchronous motor power of 5.5 kW and frequency converter, with direct-flow universal head. The machine can be supplied with angle, T-head or slotted head. For processing silicone rubber mixtures, the machine is equipped with a worm with special threading, and there is no heating of thermal control zones in the thermal automation system.

To ensure highly productive and qualitative processing of rubber mixtures by the machine, the cross-sectional area of profiled blanks and profiles should be from 0.18 to 1.8 cm2.

Specifications

Share your requirements for a quick response!

Delivery & Payment

Shipping Terms

Delivery Time

Payment Methods

Similar Products You May Be Interested In

Rubber Processing Machine MCT-2-50/80-L-CHB

View Details

Hydraulic Vulcanization Press 100-500 2E

View Details

Rubber Processing Machine MCHX-125/10-L-CHB

View Details

Portable Vulcanizing Press for Conveyor Belt Splicing PCT

View Details

Single-Screw Rubber Processing Machine MCHT-63/6-P-CHB

View Details

Rubber Processing Machine Single-Screw MChX-90/10-L-CHB

View Details

Hydraulic Vulcanization Press 40-250 1E

View Details

Polystyrene Foam Production and Processing Line Model "Penoceh-2000

View Details

Single-Screw Rubber Recycling Machine MCT-90/6-L-CHB

View Details

Single-Screw Rubber Processing Machine MCH-63/10-L-CHB

View Details

3D Printer for Creating Models - PlastoPRINT S1

View Details

Rubber Processing Machine Single-Screw MCT-125/6-L-CHB

View DetailsVerified Suppliers

All products are sourced directly from authorized Russian manufacturers

Quality Assurance

Products meet international quality standards with proper certification

Global Shipping

Reliable logistics solutions to deliver products to your location

Secure Payments

Multiple secure payment options to facilitate international transactions