Available for Import

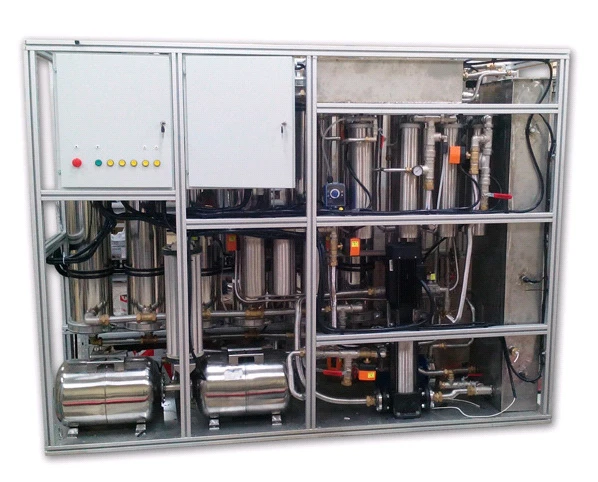

Available for ImportWater Treatment and Supply System MO-4000 for Clean Water Access

Bulk pricing available

FOB, CIF & EXW terms available

Description

The system of water treatment, water storage and water supply is designed for purification of water from open reservoirs, wells and boreholes from suspended solids, colloids, disinfection from bacteria and viruses, including spore warfare forms of BS, decontamination from SNF of organic and inorganic origin, including chemical warfare agents, decontamination from radioactive substances, purification from iron, manganese, copper, sulphur, phosphorus compounds, organic substances (including petroleum products) and dissolved salts, including compounds of one-, two- and polyvalent metals, storage of treated water and delivery of treated water under pressure to the consumer network. The system is designed for water treatment in case of contamination of water intake with radioactive, poisonous substances and bacteriological agents, both as a result of sabotage and as a result of man-made and natural disasters. The nominal capacity of the system is 4.2 m3/h (100 m3/day), which is sufficient to supply: <ul> <li>- 400 persons according to the consumption norms established for the urban population (250 litres/person/day);</li> <li>1,250 people according to the consumption norms established for APL-500 military personnel (80 litres/person/day);</li> <li>20,000 people when water is used only for drinking and cooking.</li> </ul>The system is supplied in full factory readiness, equipped with a stock of consumables, a set of tools and spare parts.

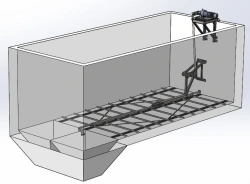

The system deployment time is 2 hours. The system consists of the following units, mounted in a single housing: a unit for storing raw water, water treatment unit, storage unit for purified water, a unit for discharging purified water into the consumer network. In appearance the system is a 20-foot container type 1C of olive-green colour.Technical characteristics of the system Water treatment technology.

Source water is accumulated in the source water storage unit, from where it enters the blocks of multipatron prefilters, where it is purified from mechanical impurities and dissolved organic substances. Then the water is fed to a two-zone countercurrent reactor for treatment with high ozone concentration (not less than 9% wt.). Ozone is produced in high-voltage high-frequency barrier discharge generators.

High ozone concentration is achieved by applying a special technology of high-efficiency cooling of high-voltage electrodes (anodes) of generators. Oxygen with concentration not lower than 95% is used as a source gas for ozone production, produced on site in oxygen concentrators, which are a part of the water treatment system equipment. To increase the life of the molecular sieves of the oxygen concentrators, the air entering the concentrators is filtered and dehumidified.

In the two-zone countercurrent reactor there is a complete disinfection of water from bacteria and viruses, including spore warfare forms of BS, oxidation with conversion into insoluble state of compounds of polyvalent metals and semi-metals (iron, manganese, copper, cobalt, mercury, bismuth, thallium, arsenic, antimony, etc.), complete or partial removal of bismuth, thallium, arsenic, antimony, etc.).etc.), complete or partial destruction of organic compounds (including complex organophosphorus, organochlorine and arsenic-containing compounds). After ozone treatment in the reactor, organic compounds are either transformed into harmless substances (H2O, CO2) or undergo partial destruction to form less toxic and easily sorbed intermediate compounds. From the reactor, water enters the inlet of a high-pressure pump and is pressurised for treatment.

Water enters the blocks of multipatron postfilters, where it is purified from mechanical impurities formed during ozone oxidation and residues of dissolved organic substances of ANM material. Destruction of ozone dissolved in water also takes place here. Further, the treated water enters the nanofiltration membrane housings, where it is separated by membranes into desalinated permeate and salt-enriched concentrate.

The concentrate is discharged from the treated water block into the sewer. To increase the interflush life of the nanofiltration membranes, an antiscalant is dosed into the water before nanofiltration. The treated water passes through a water meter, is supplied with a preserving dose of sodium hypochlorite and enters the storage tank of the treated water storage unit.

From the storage tank the treated water is supplied under pressure to the consumer's water supply network. The design of the water-dispensing unit allows to connect the system to the existing water supply networks with pumps of the second lift, to carry out water discharge without connection to the networks (in the tank), to supply water to consumers through temporary pipelines, using the pumps of the system for injection of treated water..

Specifications

Note: All specifications are provided by the manufacturer and may be subject to change. Please contact us to confirm the latest specifications before placing your order.

Share your requirements for a quick response!

Delivery & Payment

Shipping Terms

Delivery Time

Payment Methods

Similar Products You May Be Interested In

Sludge Scraper for Radial Primary Settlers IRPO

View Details

Water Treatment Installation M-1000 for Deep Desalination

View Details

Tangential Sand Separator for Wastewater Treatment

View Details

Industrial Grease Separator LOS-ZH

View Details

Biological Wastewater Treatment System LOS-R

View Details

Water Treatment System for Ice Rinks - RLT Crystal Ice

View Details

Water Purification and Supply System O-10000

View Details

Brass Mesh Filter Couplings for Water Systems, 2.5 MPa Rated Pressure

View Details

Vökker Shield Valve with Three-Sided Seal 400x400 P1

View Details

Wastewater Grinder BARRY010X - Efficient Waste Processing

View Details

Bottom Scraper for Horizontal Settlers

View Details

Water Treatment and Supply System O-200

View DetailsVerified Suppliers

All products are sourced directly from authorized Russian manufacturers

Quality Assurance

Products meet international quality standards with proper certification

Global Shipping

Reliable logistics solutions to deliver products to your location

Secure Payments

Multiple secure payment options to facilitate international transactions