Available for Import

Available for Import

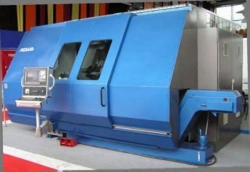

CNC Metalworking Lathe-Milling Machine ITS 250/1000 for Precision Metal Processing

Bulk pricing available

FOB, CIF & EXW terms available

Description

Metal-working machine lathe-milling numerically programmed control 1.The machine is designed for cold working of metal. 2.Machine tools are designed for turning cylindrical (with a straight, stepped and curved profile), tapered and end surfaces on parts such as bodies of rotation, as well as for cutting threads: metric, modular, inch, pitchevoy and pipe tapered. 3.Processed materials: ferrous and non-ferrous metals, cast iron, plastic.

4.The machine is equipped with a CNC (numerical control) device, which minimises the operator's participation in the process of processing the part. 5.The machine is designed for 2-shift work. 6.Accuracy resource up to the first average repair-12 thousand hours 7.Service life of the machine tool is 5 years.

8.The machine has a rigid bed, on the guides of which moves the slide and tailstock (Z-axis). On the guides of the slide carriage moves the slide with a 4 or 8-position turret mounted on it (X-axis). The left y...

Specifications

Note: All specifications are provided by the manufacturer and may be subject to change. Please contact us to confirm the latest specifications before placing your order.

Share your requirements for a quick response!

Delivery & Payment

Shipping Terms

Delivery Time

Payment Methods

Similar Products You May Be Interested In

High-Precision CNC Lathe Machine NT250S05F4

View Details

Lathe Machine with Control System SA500C30F2

View Details

CNC Lathe Machine SA500F3 for Precision Machining

View Details

CNC Wheel Turning Machine RT905F3 for Railway Wheels

View Details

CNC Turning Center for Rotational Parts Processing 1740Y-2D-1

View Details

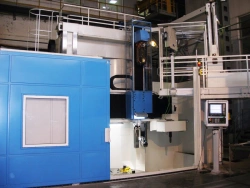

CNC Vertical Lathe Machine 1A532LMF3.SM

View Details

CNC Turning Center for Precision Machining Model 1715C-2D-0.5

View Details

SA700F3 Horizontal Lathe Machine for Precision Turning

View Details

CNC Vertical Lathe Machine 1A525MF3.SM

View Details

CNC Lathe Machine SA1400C70F4 for Precision Turning

View Details

High-Precision CNC Lathe Machine NT700F4

View Details

CNC Lathe Machine Model 16B16T1

View DetailsVerified Suppliers

All products are sourced directly from authorized Russian manufacturers

Quality Assurance

Products meet international quality standards with proper certification

Global Shipping

Reliable logistics solutions to deliver products to your location

Secure Payments

Multiple secure payment options to facilitate international transactions