Available for Import

Available for Import

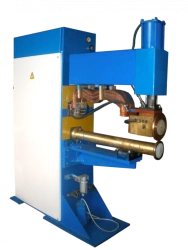

Continuous Welding Machine MSO-201 UHL4 for Low-Carbon Steel Applications

Bulk pricing available

FOB, CIF & EXW terms available

Description

Machine contact welding MSO - 201 is designed for butt welding by continuous fusion and fusion with preheating of parts made of low-carbon steel with cross-section 120 - 1400 mm2, as well as tool blanks and blanks of building structures made of low-alloy steel, including reinforcement of reinforced concrete of II and III classes, with diameter up to 32 mm inclusive. The special automatically performed precipitation process ensures the stability of welded joints quality. The machine is designed for operation in the following conditions: ambient temperature from plus 1° C to plus 35° C, ambient humidity up to 80% at 25° C, atmospheric pressure from 84.0 kPa (630 mmHg) to 106.7 kPa (800 mmHg). Category 4 provides for operation of the machine in closed heated (cooled) and ventilated rooms.

Specifications

Note: All specifications are provided by the manufacturer and may be subject to change. Please contact us to confirm the latest specifications before placing your order.

Share your requirements for a quick response!

Delivery & Payment

Shipping Terms

Delivery Time

Payment Methods

Similar Products You May Be Interested In

Argon Arc Welding Machine TT573-2000

View Details

Single-Phase Transformer TDM-402 U2

View Details

Thermostatic Table NP 10-6 PRO with Temperature Regulator TP 1-10 0.5

View Details

Welding Power Supply Unit ADD-5001 I U1

View Details

Contact Welding Machine MSh-2203 UHL4

View Details

Welding Machine ADD - 2x2502.1 PR and U1

View Details

Thermostatic Table NP 6-5 PRO with Temperature Controller TP 1-10 0.5 for PCB Heating

View Details

GD-2x2503 U2 Welding Generator - Model 06

View Details

Large Size Thermostatic Table NP 34-24 PRO with Temperature Regulator TP 2-10 KD PRO

View Details

Welding Generator ADG - 2x2502.1 VG and U1 Sever

View Details

Large PCB Heating Table NP 24-17 PRO with Temperature Regulator TP 1-10 KD

View Details

Welding Machine ADD-4008 I U1 for Manual Arc Welding

View DetailsVerified Suppliers

All products are sourced directly from authorized Russian manufacturers

Quality Assurance

Products meet international quality standards with proper certification

Global Shipping

Reliable logistics solutions to deliver products to your location

Secure Payments

Multiple secure payment options to facilitate international transactions