Available for Import

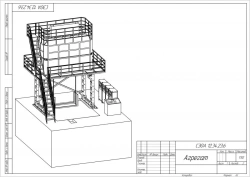

Available for ImportElevator Furnace SGO 6.6.6/14 STC for Efficient Heating Applications

Bulk pricing available

FOB, CIF & EXW terms available

Description

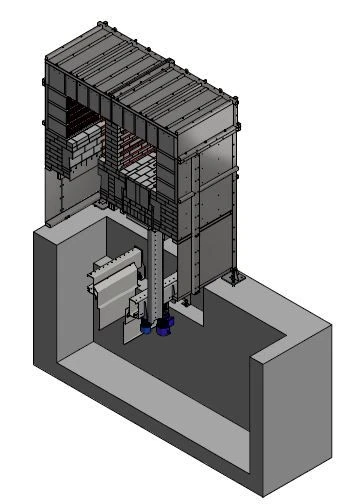

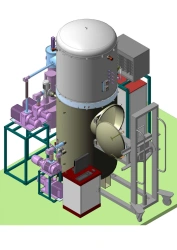

Elevator furnace OPP 6.6.6/14 STC Purpose: Elevator furnace with two sliding benches and one chamber with two heating zones separated by heating elements, designed for heating combined refractory casting moulds up to the temperature of 1400 degrees Celsius for subsequent out-of-furnace pouring with melt and crystallisation. Design features: Electronic control cabinet with digital temperature indication.

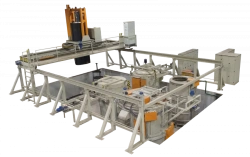

2 lower loading and unloading windows and 2 sliding trays, controlled independently of each other. Remote control of the tray movement. Loading and unloading of the moulds on the tray is carried out manually outside the furnace chamber.

Welded frame construction. Frame material - sheet steel. Ceramic fibre lining.

Advantages: Increased energy efficiency and energy saving during operation. Increased overhaul period and service life of heaters and lining. Increased yield of finished products.

Specifications

Note: All specifications are provided by the manufacturer and may be subject to change. Please contact us to confirm the latest specifications before placing your order.

Share your requirements for a quick response!

Delivery & Payment

Shipping Terms

Delivery Time

Payment Methods

Similar Products You May Be Interested In

Hydrogen Resistance Heating Furnace SGNF Type

View Details

Electric Pusher Furnace for Ceramics STZ 6.2.45, 5.5/9.5

View Details

Cap Type Resistance Electric Furnace SGO

View Details

Vacuum Electric Thermal Installation KB 142

View Details

Low-Temperature Chamber Electric Oven NK 6.6.6/3.5

View Details

Laboratory Electric Oven for Heating and Analytical Work PL 10/14

View Details

Thermal Processing Electric Furnace for Heating, Model SSZA

View Details

Two-Chamber Vacuum Resistance Electric Furnace for Hardening D-2.2, E-13.5UT-IVT-M

View Details

Vertical Vacuum Resistance Electric Furnace B-5.5.E-12SV-IVT-F

View Details

Chamber Electric Furnace for Industrial Applications, Model PK

View Details

Laboratory Electric Furnace PL 5/12.5

View Details

Aluminum Alloy Quenching Unit Elevator Type SEOA 12.34.23/6

View DetailsVerified Suppliers

All products are sourced directly from authorized Russian manufacturers

Quality Assurance

Products meet international quality standards with proper certification

Global Shipping

Reliable logistics solutions to deliver products to your location

Secure Payments

Multiple secure payment options to facilitate international transactions