Available for Import

Available for Import

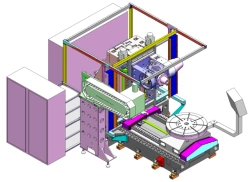

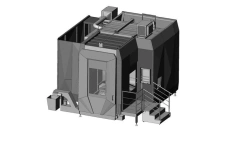

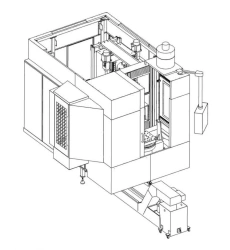

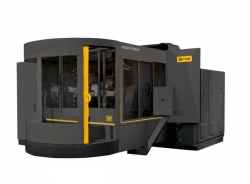

Horizontal milling machining centre STC H 63x2C

Manufacturer:

ISZ LLC

Price:

Request Quote

Bulk pricing available

FOB, CIF & EXW terms available

Available Models

Description

High-speed horizontal milling machining centre model STC H 63x2C (SUPER CENTRE IS630) is designed for complex machining of particularly complex body parts made of aluminium, cast iron, steel and magnesium alloys.

The machine can perform operations of drilling, countersinking, reaming, boring of precise holes on precise coordinates, milling of planes and grooves, milling of precise holes with milling cutters, threading with taps, cutters and milling cutters, machining of shaped surfaces with simultaneous control on four coordinates, work with measuring heads.

The machine can perform operations of drilling, countersinking, reaming, boring of precise holes on precise coordinates, milling of planes and grooves, milling of precise holes with milling cutters, threading with taps, cutters and milling cutters, machining of shaped surfaces with simultaneous control on four coordinates, work with measuring heads.

Specifications

Type of product according to PP RF 616

Horizontal machining centers 4-axis 3-axis)

Length

6000 mm

Width

4200 mm

Height

3650 mm

Machine type

Machining centre STC H 63x2C

Machine weight

16000 kg

Maximum tool length

550 mm

Maximum tool diameter

125 mm

Capacity of tool magazine, pcs. 60

60 pcs

Maximum feed force in X/Y (down)/Y (up)/Z axes

kN 4 / 4 / 2 / 3

Maximum programmable movements

mm: - x-axis (rack transversely) 800 - y-axis (spindle headstock vertically) 710 - z-axis (table longitudinally) 630 mm

Maximum spindle/spindle motor torque

nm 700/ 300*

Maximum spindle/motor-spindle speeds

6000/8000 -12000*

Maximum table torque in the B axis

nm 750

Table load capacity

600 kg

Maximum size of workpiece to be mounted D x H

800x710 mm

Time of change of satellite tables

B1/B8 2100/900 MHz

Number of satellite tables

2 pcs

Working surface size of the satellite table

630x630 mm

Working feed rate limits of the rotary table in the B axis,

deg/min 1 .... 10800 °C

Working feed rate limits in X, Y, Z axes,

mm/min 1 .... 60 000 mm

Speed of fast movements in X, Y, Z axes,

m/min 60 m

Coolant supply

Through nozzles on spindle headstock; l/min 100 soot supply for chip flushing; l/min 100 soot supply through spindle (pressure 5 mpa); l/min 20 l

Note: All specifications are provided by the manufacturer and may be subject to change. Please contact us to confirm the latest specifications before placing your order.

Share your requirements for a quick response!

Instant response in 15 minutes

Best wholesale prices guaranteed

Direct from manufacturer

Delivery & Payment

Shipping Terms

Delivery Time

Sea freight: 30-60 days (depending on destination)

Air freight: 14-21 days (for urgent orders)

Payment Methods

Similar Products You May Be Interested In

Five-Axis CNC Machining Center for Complex Material Processing, Model MS-5X

View Details

CNC Machining Center 2628F4

View Details

Vertical 5-Axis Machining Center 900VH and Modification 900VHT

View Details

CNC Machining Center for Precision Parts - VFC 1000

View Details

5-Axis Machining Center 2000VH and 2000VHT

View Details

900H Machining Center for Comprehensive Milling and Turning

View Details

Vertical CNC Machining Center DMC 635 V Ecoline

View Details

High-Speed Five-Axis Horizontal Machining Center STC N 80 SG

View Details

Heavy Horizontal Machining Center IR1600MF4

View Details

CNC Lathe-Milling Center NT500C10-5X

View Details

900VH Machining Center for Comprehensive Milling Operations

View Details

High-Speed Horizontal Machining Center Super Center IS800

View DetailsVerified Suppliers

All products are sourced directly from authorized Russian manufacturers

Quality Assurance

Products meet international quality standards with proper certification

Global Shipping

Reliable logistics solutions to deliver products to your location

Secure Payments

Multiple secure payment options to facilitate international transactions