Available for Import

Available for Import

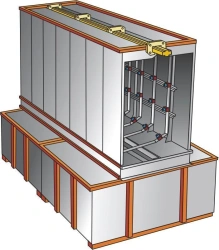

PCB Flux Cleaning System SM16Pro for Effective Circuit Board Cleaning

Manufacturer:

DIPOL TECHNOLOGIES OJSC

Price:

Request Quote

Bulk pricing available

FOB, CIF & EXW terms available

Description

Purpose: washing of mounted printed circuit boards from flux, solder paste and other technological means used in the process of soldering.

Functions: washing with washing liquid; preliminary rinsing; finishing rinsing; drying with hot air; rinsing with deionised water; automatic water refilling into tanks.

Advantages: equipment of Russian design and manufacture; high efficiency of board cleaning due to increased parameters of pressure and temperature of supplied liquid; possibility of flexible setting of washing modes and connection to PC; simplicity and efficiency in maintenance and operation; possibility of moving through standard doorways.

Functions: washing with washing liquid; preliminary rinsing; finishing rinsing; drying with hot air; rinsing with deionised water; automatic water refilling into tanks.

Advantages: equipment of Russian design and manufacture; high efficiency of board cleaning due to increased parameters of pressure and temperature of supplied liquid; possibility of flexible setting of washing modes and connection to PC; simplicity and efficiency in maintenance and operation; possibility of moving through standard doorways.

Specifications

50 Hz AC mains power supply

380 V

Overall dimensions (DxWxH), not more than

1700 mm

Dimensions of printed circuit boards, not more than

350 mm

Number of printed circuit boards

4 pcs

Maximum temperature in the rinse liquid supply system

65 °C

Maximum temperature in the water supply system of the rinse circuits

40 °C

Maximum pressure in liquid supply system

4

Electrical safety

Protective earthing of the system enclosure and the main electrical devices within it, automatic differential switches in the control circuits of electrical devices, phase control relays.

Temperature range in air drying mode

45...120 °C

Conductivity range in circuits with deionised water

1...1000

Control of liquid level in tanks

automatic with level sensors

Operating temperature

15...35 °C

Relative humidity during operation

80 %

Note: All specifications are provided by the manufacturer and may be subject to change. Please contact us to confirm the latest specifications before placing your order.

Share your requirements for a quick response!

Instant response in 15 minutes

Best wholesale prices guaranteed

Direct from manufacturer

Delivery & Payment

Shipping Terms

Delivery Time

Sea freight: 30-60 days (depending on destination)

Air freight: 14-21 days (for urgent orders)

Payment Methods

Similar Products You May Be Interested In

Chemical Cleaning System for Manual or Automatic Washing CLEVCLEAN240A

View Details

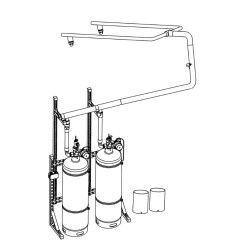

Gas Fire Extinguishing Modules MPA-KD (50-XX-50)

View Details

Ceramic Glazing Spray Booth "Tornado

View Details

Gas Fire Suppression Module MPA-KD 65-XX-50

View Details

High-Pressure Spraying Equipment for Two-Component Liquids Proton E-5

View Details

Universal Fire Monitor with Remote Control LSD-C20(15,25)U

View Details

Liquid Jet Cleaning Chamber MK

View Details

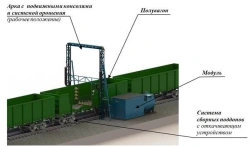

Portable Technological Equipment Complex for Anti-Icing and Dust Control

View Details

Surface Preparation Equipment Set for Welding, Model OPPS

View Details

Gas Fire Extinguishing Module M05 (65-100-40)

View Details

Compact Portable Technology Complex for External Cleaning of Railway Tank Car Boilers

View Details

MPA-KD Gas Fire Suppression Modules (50-XX-33)

View DetailsVerified Suppliers

All products are sourced directly from authorized Russian manufacturers

Quality Assurance

Products meet international quality standards with proper certification

Global Shipping

Reliable logistics solutions to deliver products to your location

Secure Payments

Multiple secure payment options to facilitate international transactions