Available for Import

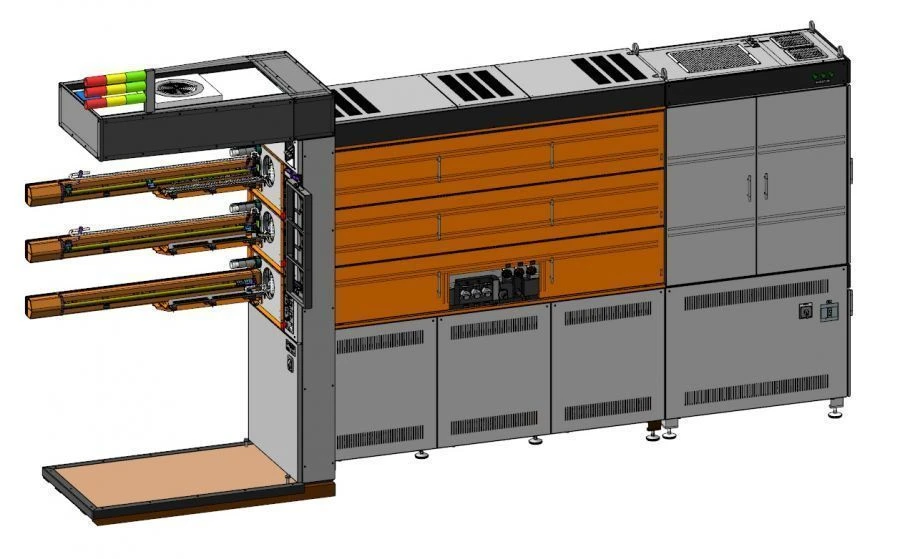

Available for ImportSingle-Zone Multi-Tube Diffusion System SDOM-3/100 for Silicon Plate Processing

Bulk pricing available

FOB, CIF & EXW terms available

Description

System diffusion single-zone multi-tube model SDOM-3/100 is designed for automatic gas-thermal treatment of silicon wafers with a diameter of 50 ... 100 mm by diffusion and oxidation in the flow of vapour-gas mixture in the chamber of an open (direct-flow) quartz reactor in the production of semiconductor electronics products at temperatures from 600 ° C to 1200 ° C (briefly up to 1300 ° C). Internal diameter of the heating chamber, mm-160; Internal diameter of the heating element not less than 180 mm; The length of the working heat zone is not less than 600 mm; Time of heating up the electric furnace to the maximum working temperature not more than - 2 hours; Working medium gaseous: argon, oxygen, nitrogen, - humidified oxygen (humidified nitrogen); <ul> <li>- temperature distribution error along the length of the working zone, not more, °?

- ±1.0.</li> </ul>Average service life is not less than 6 years. Overall dimensions DxWxH, mm not more: 4000x1030x2850; Weight, kg, not more than 2200.

Specifications

Share your requirements for a quick response!

Delivery & Payment

Shipping Terms

Delivery Time

Payment Methods

Similar Products You May Be Interested In

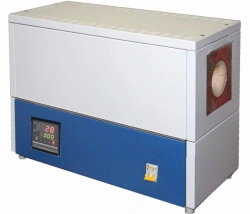

Laboratory Muffle Furnace for Chemical Analysis LF-2/13-G1

View Details

Tubular Furnace LOIP LF-50/500-1200 for Heat Treatment

View Details

Climate Chamber for Controlled Environment Testing

View Details

Vacuum Post for Electric Vacuum Processing EVO-15/6-350

View Details

Laboratory Muffle Furnace for Ashing LF-7/11-V2

View Details

Laboratory Muffel Furnace LF-7/13-V2

View Details

Low-Inertia Tube Furnace with Temperature Regulator MTP-2MR

View Details

Infrared Convection Oven AПИК 2.2

View Details

Vertical Shaft Furnace LOIP LF-70/13-G1

View Details

Laboratory Muffle Furnace for Sample Preparation LF-15/11-G2

View Details

Salt Bath Furnace for Heating Parts - SVS Model

View Details

Temperature and Pressure Testing Chamber REOCAM TCA-2000

View DetailsVerified Suppliers

All products are sourced directly from authorized Russian manufacturers

Quality Assurance

Products meet international quality standards with proper certification

Global Shipping

Reliable logistics solutions to deliver products to your location

Secure Payments

Multiple secure payment options to facilitate international transactions