Available for Import

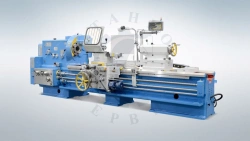

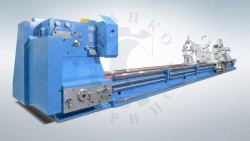

Available for ImportSpecial Turning-Roller Machine RT30101 for Precision Machining Applications

Manufacturer:RSZ LLC

Price:Request Quote

Bulk pricing available

FOB, CIF & EXW terms available

Description

Specialised lathe-rolling machines ??30101 are designed for machining of the tread part of the axle of the carriage wheelset, performing various turning operations, as well as thread cutting: metric, inch, modular and pitch.

Specifications

Type of product according to PP RF 616

Universal lathes and screw-cutting machines, with CNC, CNC)

Length

5190 mm

Width

1780 mm

Height

1550 mm

Roughness of the cylindrical surface of the sample product after its finish machining

Ra 2.5 µm

Roller knurling force

2200 kg

Total power of electric motors installed on the machine tool

16.65 kW

Main motion drive power

15 kW

Maximum torque on the headstock spindle

3.0 kNm

Speed of rapid transverse movements of the slide

2000 mm/min

Speed of rapid longitudinal movements of the caliper

5200 mm/min

Step limits for machinable pitch threads

112-0.5 pitch diametral

Step limits for machinable modular threads

0.25-56 module

Step limits for machinable inch threads

28-0.25 threads per 1 inch.

Step limits for machinable metric threads

1...224 mm

Spindle speed limits

10...1250

Profile radius of the smoothing roller

SBVVBG mm

Profile radius of hardening roller

15 mm

Diameter of the knurling roller

130 mm

Height of the mounted pick in the pick holder

32 mm

Longest length of knurling machining

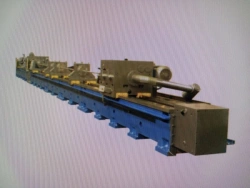

2200 mm

Longest length of turning operation

2800 mm

Maximum mass of the workpiece to be installed

2500 kg

Maximum diameter of knurling machining

212 mm

Minimum diameter of knurling treatment

Flat grinder, Specialised grinder mm

Largest diameter of the workpiece to be machined above the bed

630 mm

The largest diameter of the workpiece to be mounted over the knurling unit.

240 mm

Largest diameter of the workpiece to be mounted and machined above the slide

350 mm

Largest diameter of the workpiece to be mounted above the bed

700 mm

Machine weight (with electrical equipment)

6500 kg

Machine accuracy class according to GOST 8-82

?

Note: All specifications are provided by the manufacturer and may be subject to change. Please contact us to confirm the latest specifications before placing your order.

Share your requirements for a quick response!

Instant response in 15 minutes

Best wholesale prices guaranteed

Direct from manufacturer

Delivery & Payment

Shipping Terms

Delivery Time

Sea freight: 30-60 days (depending on destination) Air freight: 14-21 days (for urgent orders)

Payment Methods

Similar Products You May Be Interested In

Universal Lathe Machine for Turning and Thread Cutting 16K40PF1-1

View Details

Resonance Balancing Machine with Horizontal Axis VM-010

View Details

Universal Lathe and Screw-Cutting Machine Samat 400 XV

View Details

Precision Lathe Machine RT317-8 for Turning and Threading

View Details

Universal Lathe Machine Model 16P25P-1.5

View Details

Precision Lathe Machine RT317-6 for Turning and Threading

View Details

Deep Hole Processing Machine Model 2825P

View Details

Precision Lathe Machine for Turning and Thread Cutting 1Н65-6

View Details

Precision Lathe Machine 1N65-1 for Turning Operations

View Details

STPR-200 Chuck Lathe with Revolving Head and CNC Control

View Details

Precision Lathe for All Turning Operations - RTS117-6

View Details

Lightweight Turning and Screw-Cutting Lathe IT-1GE

View DetailsVerified Suppliers

All products are sourced directly from authorized Russian manufacturers

Quality Assurance

Products meet international quality standards with proper certification

Global Shipping

Reliable logistics solutions to deliver products to your location

Secure Payments

Multiple secure payment options to facilitate international transactions