Available for Import

Available for Import

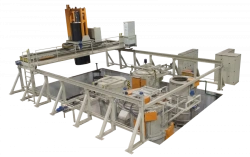

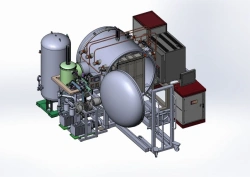

Vacuum Electric Thermal Installation KB 153 for Hydrogen Sealing Applications

Bulk pricing available

FOB, CIF & EXW terms available

Description

Vacuum electrothermal furnace KB 153 two-cup hydrogen furnace is designed for the production of glass spheres of single and multi-contact germanowires in two gas environments (hydrogen-nitrogen-hydrogen, nitrogen), as well as for soldering of precision parts with silver solders in hydrogen environment at temperatures up to 1200C. The furnace is a gas-filled batch electric furnace with a stationary hearth and vertically moving heating chambers (hoods). Each hood is equipped with two observation windows located at the same level. A separate gas system is provided for each hood to prepare the second hood for operation while the first hood is in operation. The gas system provides formation and dosing of the working gas supply (pure hydrogen, nitrogen or formargaz) into the heating chamber during the technological process, humidification of the gas to the required value. The heater is made of nichrome bars.

Specifications

Share your requirements for a quick response!

Delivery & Payment

Shipping Terms

Delivery Time

Payment Methods

Similar Products You May Be Interested In

VESTA Electric Hot Plate Model EPP-2-2.4/220

View Details

Resistance Electric Furnace with Oxidizing Atmosphere, Model CNO

View Details

Resistance Electric Furnace for Shaft Applications, Model SShO

View Details

Thermal Processing Electric Furnace with Oxidizing Atmosphere - SGOA Model

View Details

Vacuum Chamber Resistance Furnace for Annealing D-6.9.6-11.5TT-R

View Details

Vacuum Electric Thermal Installation KB 154

View Details

Electric Resistance Furnace for Thermal Processing in Air

View Details

Resistance Cap Furnace for Heat Treatment SGO

View Details

Laboratory Electric Tube Furnace SUOL-0.3.2.5/12.5

View Details

High-Temperature Vacuum Installation KB 134

View Details

Chamber Furnace for Metal Heating "SPARTA

View Details

Vacuum Chamber Resistance Furnace SNVS-3.3/17-I2-2VO

View DetailsVerified Suppliers

All products are sourced directly from authorized Russian manufacturers

Quality Assurance

Products meet international quality standards with proper certification

Global Shipping

Reliable logistics solutions to deliver products to your location

Secure Payments

Multiple secure payment options to facilitate international transactions