Available for Import

Available for Import

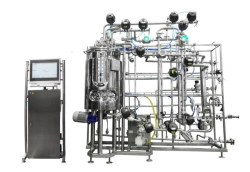

High-Density Coating System KN-9 for Effective Tool Coating Applications

Manufacturer:

LVT+ LLC

Price:

Request Quote

Bulk pricing available

FOB, CIF & EXW terms available

Description

The KN-9 coating unit is designed for preparation and application of high density coatings (AlTiN, AlTiSiN,TiB2) for end tools and cutting inserts with deposition rate not less than 1.9 microns/hour, ion-plasma low-temperature nitriding of workpiece surface, application of various coatings:

- hardening coatings: AlTiN, AlCrN, AlSiTiN, AlSiCrN;

- multiphase coatings: -TiN/nc-AlN, nc-TiAlN/a-Si3N4, etc;

- heat-resistant and heat-resistant coatings.

- surface nitriding

Coating methods and technologies: PVD, CVD, HiPIMS, CAE, CMS, PECVD, PN/C, PARNS, IPVD based on vacuum arc vaporisation (ARC) or magnetron method and their combinations.

- hardening coatings: AlTiN, AlCrN, AlSiTiN, AlSiCrN;

- multiphase coatings: -TiN/nc-AlN, nc-TiAlN/a-Si3N4, etc;

- heat-resistant and heat-resistant coatings.

- surface nitriding

Coating methods and technologies: PVD, CVD, HiPIMS, CAE, CMS, PECVD, PN/C, PARNS, IPVD based on vacuum arc vaporisation (ARC) or magnetron method and their combinations.

Specifications

Assignment

Designed for high density coating, for end tools and cutting inserts with deposition rate not less than 1.9 microns/hour, for ion-plasma low-temperature nitriding of workpiece surface and application of various functional coatings

Dustproof

Got it

Type of construction

Stationary

Guaranteed lifetime of the plant

12 months from the date of signing the commissioning certificate of the plant

Warranty shelf life of the system

18 months from the date of delivery

Service life of the plant until decommissioning

5 years

Resources and service life of components and purchased products

are determined in accordance with their operating documents

Climatic designs

GOST 15150-69; GOST 15543-70 at normal values of climatic factors of external environment - UHL for product placement category 4.2.

Execution

according to design documentation LSMC.15101.00.00.00.00 Coating Application Installation KN-9

Installed capacity

121715 W

Maximum power consumption

No more than 100 kW

Power supply voltage

380(10±15%) V

Power supply connection diagram

TN-C (three-phase four-wire, zero protective and zero working conductors are combined in one conductor).

Maximum current consumption by phase

184,42 A

Ultimate vacuum

not more than 6-10-?

Chamber pressure 30 minutes after the start of pumping

not more than 5-10-³

Air flow after pumping the chamber for 30 min, ncm³/min

Not more than 0.3

Maximum working temperature for heating workpieces

600 °C

Working gases

argon GOST 10157-2016, nitrogen GOST 9293-74, hydrogen GOST 3022-80, air

Number of gas supply channels

5 pcs

Pressure control range by gas flow

0,1-0,5

Working fluid (recommended)

Distilled water, 20% solution of ethyl alcohol in distilled water according to GOST 6709-72

Working fluid volume, l

No more than 15

Cooling water flow rate, m³/hour

max, 1.5

Compressed air flow rate, m³/min

Not more than 0.02

Weight of the unit (excluding the forevacuum unit, cryogenic pump compressor unit, water recycling system,

no more than 2300 kg

Overall dimensions of the unit on the transport base (length x width x height)

max. 2800 x 1230 x 2260 mm

Note: All specifications are provided by the manufacturer and may be subject to change. Please contact us to confirm the latest specifications before placing your order.

Share your requirements for a quick response!

Instant response in 15 minutes

Best wholesale prices guaranteed

Direct from manufacturer

Delivery & Payment

Shipping Terms

Delivery Time

Sea freight: 30-60 days (depending on destination)

Air freight: 14-21 days (for urgent orders)

Payment Methods

Similar Products You May Be Interested In

Automated Ion-Plasma Coating System MAP-3

View Details

Biotechno Filtration Systems - Polymer Membrane Based

View Details

Autoclave System AYT-2000-12800-10-EV for PKM Molding

View Details

Autoclave System for Molding PCM Products, Model AУТ 4000-7000-12-ЭВ

View Details

Vertical Fermentation Vessel for Liquid Food Storage - ESV Series

View Details

Biorus® Fermenter for Aerobic and Anaerobic Cultivation

View Details

Optimal Climate Drying Chamber INSTALIKA ALFA

View Details

Kepler Vacuum Coating System for Large-Scale Applications

View Details

Food Storage and Transport Tank Series Y1-OSV

View Details

Oil Quenching Bath, Model VZM

View Details

Friction Welding Machine PSTI-400 for Gas Turbine Rotors

View Details

Biotechno Bioreactors for Cell Culture (5 to 3,000 liters)

View DetailsVerified Suppliers

All products are sourced directly from authorized Russian manufacturers

Quality Assurance

Products meet international quality standards with proper certification

Global Shipping

Reliable logistics solutions to deliver products to your location

Secure Payments

Multiple secure payment options to facilitate international transactions