Available for Import

Available for Import

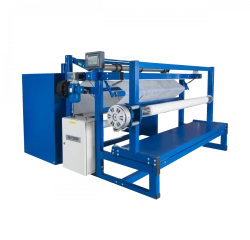

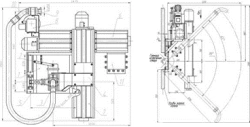

Multifunctional Measuring and Defect Inspection Machine B01.31 for Non-elastic and Slightly Elastic Materials

Bulk pricing available

FOB, CIF & EXW terms available

Description

The measuring table B01.31 is a multifunctional complex combining the functions of a 3 metre measuring table and a measuring and rejecting machine. The machine works with bales weighing up to 60kg and with a diameter of up to 400mm. It is available in bale widths from 1800 mm / up to 2000 mm / up to 2500 / up to 3200 mm / up to 3500 mm. The machine is equipped as standard with a roll edge levelling system, automatic material stretch tracking system, electronic programmable metre counter, forward and reverse stroke with twisting into a roll, viewing screen with LED illumination, roll end sensor, etc. The machine can be additionally equipped with a device for static removal, density adjustment of the coil winding, cutting manual or automatic knife, Astra software for accounting of uncoiled materials, weighing system of the coiled coil, adjustment of the width of the backlight, additional sensor tear.

Specifications

Note: All specifications are provided by the manufacturer and may be subject to change. Please contact us to confirm the latest specifications before placing your order.

Share your requirements for a quick response!

Delivery & Payment

Shipping Terms

Delivery Time

Payment Methods

Similar Products You May Be Interested In

VK-2450P Calender Ironing Machine for Efficient Drying and Ironing

View Details

Smooth Ironing Roller VГ-1218 for Efficient Drying

View Details

Rolltex B03.1 Longitudinal Cutting Machine

View Details

Long-Distance Water Blowing Apparatus OVD 221EOB002-02

View Details

Material Unwinding Machine C01.1

View Details

Measuring and Inspection Machine Model B01.41 for Non-Elastic and Slightly Elastic Materials

View Details

Measuring and Defect Inspection Machine B02.4 for Elastic and Non-Elastic Materials

View Details

Measuring and Defect Inspection Machine Model B02.10 for Elastic and Non-Elastic Materials

View Details

VK-1640P Calender Ironing Machine for Efficient Drying and Ironing

View Details

Ironing Table with Steam Generator LGS-156.00

View Details

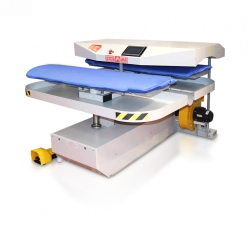

Industrial Carousel Ironing Press VR-150

View Details

Measuring and Rewinding Machine Model B02.11

View DetailsVerified Suppliers

All products are sourced directly from authorized Russian manufacturers

Quality Assurance

Products meet international quality standards with proper certification

Global Shipping

Reliable logistics solutions to deliver products to your location

Secure Payments

Multiple secure payment options to facilitate international transactions