Russian CNC Milling and Turning Machines Products

Featured Products

High-Precision Wire EDM Machine DIPOL600F03

Universal Milling CNC Machine FS-300M

Coordinate-Boring Machine 2E450AF30

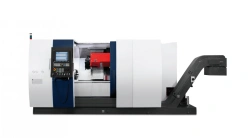

CNC Lathe Machine SA500C10F3

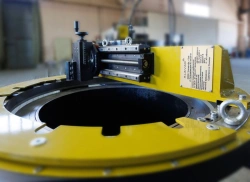

Resonance Balancing Machine with Horizontal Axis VM-36000

Precision Lathe Machine for Turning and Thread Cutting RTS117F1-3

SGPK-300 Belt Grinding Machine for Precision Grinding

Horizontal Milling Machine NGF-110SH4 with Vertical Milling Head VFG-07

CNC Lathe Machine "MT-95" by UNIMATIC with IntNC PRO System

Semi-Automatic Band Saw with Rotating Table Model LPSG350.45

RWL2020 Rail-Mounted Wheel Lathe (Export Version)

Precision Turning and Thread Cutting Lathe RTS117-3

Mobile Orbital Turning Machine AB-60T

STPR-200 Lathe Machine with Revolving Head and CNC Control

Turning and Thread Cutting Machine Model 16R25P-1

Universal Cylindrical Grinding Machine Model KSH-400.2 with CNC

CNC Lathe Machining Center for Rotating Parts Model 1728C-2D-1

CNC Gear Cutting Machine Model 5C280PF3

CNC Turning Center for Precision Machining Model 1715C-2D-0.5

Universal Milling Machine FS-400-06P

CNC Milling Machine with Software ADM SYSTEM X10

CNC Milling Machine with Software ADM SYSTEM X5

Vertical Drilling Machine with Adjustable Table 2C125MP

Horizontal Hydraulic Broaching Machine 7HBM14

Precision Lathe Machine 16K20 for Various Shaping Tasks

Universal CNC Lathe CTX 310 V1 Ecoline

Ring Foundation Processing Machine OF-560A

Semi-Automatic Bandsaw Machine with Rotating Table LPSG520.45

Universal Vertical Milling Machine 6820F1

CNC Lathe Machine "MT-45" by UNIMATIC with IntNC PRO System

CNC Turning Center for Complex Processing Model 1728

Precision Lathe Machine 1M63H for Metalworking

Horizontal CNC Lathe Machine Proton T Model T500

Horizontal Milling and Boring Machine 650H with Automatic Tool Change and CNC

Precision Lathe Machine with Control System SA750C40F2K

CNC Center Lathe Machine 16R30F3 for Precision Machining

Vertical Drilling Machine 2M112 for Precision Drilling

Grinding and Sharpening Machine TSh 3M RP

Special Milling Machine FB-126 for Comprehensive Processing

Horizontal Boring Machine with CNC, Model HVM-T

Band Saw Machine for Cutting Steel and Alloys, Model 8535

Grinding and Sharpening Machine TSh 3M.25 with Vacuum PP-750/U

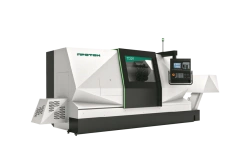

Horizontal CNC Lathe Machine Proton T320

High Precision Turning and Thread Cutting Machine 250 ИТВМ.Ф1

Precision Turning and Screw Cutting Machine AT250-500.F1 with Frequency Drive

Universal Cylindrical Grinding Machine 3U142MVL

Universal Round Grinding Machine KSH-600 with Control Panel

CNC Lathe Machine "MT-65" Unimatic with IntNC PRO System

Hydroabrasive Cutting Machine MAXIEM 0707

About CNC Milling and Turning Machines

Welcome to our CNC Milling and Turning Machines category, where you will find a comprehensive range of machines designed to meet the diverse needs of businesses across Africa, the Middle East, and South Asia. These machines are essential for enhancing productivity in industries such as manufacturing, automotive, construction, and more.

Business Solutions and Operational Needs

Our CNC Milling and Turning Machines are pivotal in solving various business challenges. They are used to produce precise components, improve production efficiency, and reduce manual labor. These machines are ideal for businesses looking to scale operations and meet increasing demand.

Applications and Use Cases

These machines are frequently utilized in sectors like engineering workshops, automotive part manufacturing, and metal fabrication companies. They are perfect for large-scale production as well as custom manufacturing, making them versatile for different operational setups.

Key Technical Characteristics

- Metal Turning Lathes: Ideal for shaping metal parts, these lathes offer single spindle options with electric motor drives. They cater to a processing range of 1200 to 3200 and are suitable for large and small batch production.

- Metal Deburring Machines: Perfect for smoothing edges and surfaces post-machining, ensuring high-quality finishes on metal components.

- Metalworking Drilling and Threading Machines: These machines handle precision drilling and threading tasks, essential for producing high-accuracy parts.

- Slitting, Sawing, Cutting Machines: Designed for cutting and shaping metal sheets and bars, these machines are critical for industries like construction and metal fabrication.

End Users

Typical users include manufacturing plants, automotive factories, metalworking workshops, and construction companies. These machines are also suitable for industrial equipment suppliers and wholesale distributors looking to expand their product offerings.

Relevance for the African Market

The robustness and precision of our CNC Milling and Turning Machines make them particularly well-suited for the African market. They are engineered to withstand demanding environments and provide reliable performance, making them a cost-effective choice for businesses looking to enhance their operational capabilities.

Profit-making Potential

Importing and distributing these machines offers significant profit opportunities. Their durability and efficiency mean lower maintenance costs and higher productivity rates, providing a strong return on purchase for resellers and end users alike.

Why Choose Russian-Made Products?

Our Russian-made machines are known for their stronger construction and reliability. They are more affordable than many European alternatives and offer better performance in harsh operational conditions. These qualities make them an excellent choice for businesses in developing markets.

Explore our extensive range of CNC Milling and Turning Machines and find the right solution to boost your business operations today.

Frequently Asked Questions

To order products from Russia through our platform, select the product you're interested in, click the "Request Quote" button, and fill out the request form. Our managers will contact you to clarify the details and provide a commercial proposal.

We offer various payment methods, including prepayment, partial payment, irrevocable letter of credit, and other options. Payment terms are discussed individually for each deal and depend on the order volume, delivery country, and supplier requirements.

We deliver Russian products to any point in the world. Our company has well-developed logistics routes and partnership relationships with transport companies, which allows us to organize delivery as efficiently as possible.

Yes, we work with requests for supply of products that are not in our catalog. Send us a technical assignment or describe the required product, and we'll find a suitable manufacturer in Russia.