Russian Semiconductor Manufacturing Tools Products

Featured Products

Vacuum Coating Machine UHN-71P-3M-2

Vacuum Coating System UHN-74P-3M-1 for Metal Film Application

Plasma-Chemical Deposition Vacuum System with ICP Source - Izofaz TM 200-01

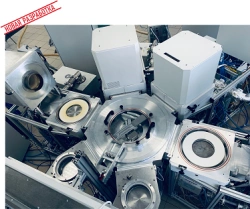

Four-Position Vacuum Coating System with Magnetron Sputtering MAGNA TM 5

Plasma Chemical Etching Vacuum System with ICP Source and Cassette Loading TM 300

Vacuum Coating System for Metallic Films Oratoria 29M

Molecular Layer Deposition System UМН-4П/Д150

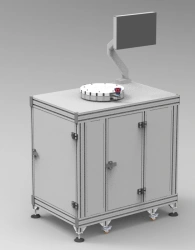

Compact Vacuum Coating System for Magnetron Sputtering, Model MVU Magna 12

Compact Plasma Cleaning Vacuum System for Photoresist Removal and Sterilization TM 4

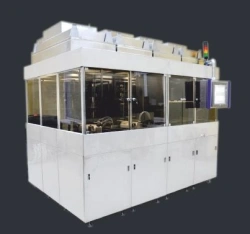

Industrial-Oriented Technological Complex Cluster TM 200

Gallium Nitride Epitaxy System for Power Transistors TM 200-01

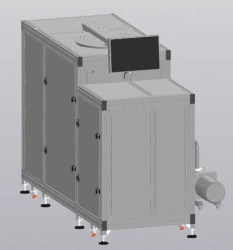

Vacuum Coating System with Magnetron Sputtering and Cassette Loading MAGNA TM 29

Plasma Chemical Deposition Vacuum System with ICP Source and Cassette Loader

Deep Anisotropic Etching Vacuum System MVU TM PLASMA 06

High-Density Coating Application System NIKA-15101

Solder Paste Melting Oven with Ethernet Control - Raduga 11

Plasma Chemical Anisotropic Selective Etching System Plasma TM 200-01

Vacuum Coating System UVN-71P-3M-1

Magnetron Sputtering Vacuum Coating System Magna TM 22

Vacuum Soldering Oven R200

Magnetron Sputtering Vacuum Coating System MAGNA TM 7

Thin Film Deposition System for Metals, Alloys, and Dielectrics

Magnetron Sputtering Vacuum Coating System Magna TM 22

Plasma Etching Vacuum System with ICP Plasma Source TM 9

Anisotropic Plasma Etching System for Silicon Plates up to 200 mm – ESTOХORS

Reactive Ion Etching Vacuum System with Load Lock PLASMA TM 7

Thermal Radiation Oven for Drying Paints and Solder Paste

Vacuum Soldering Furnace R160C

High-Density Coating Application System NIKA-15102

Oratoria 9-1 Vacuum Coating System

Reactive Ion Etching Vacuum System with Cassette to Cassette Load, Plasma TM 8

Photolithography Cluster Line - Advanced Processing Modules

Optical Parts Final Cleaning Machine UO-30PM

Four-Position Vacuum Coating System with Magnetron Sputtering and Electron Beam Evaporation, Model: 4P-VAC-2023

Molecular Layer Deposition System for Functional Nanocoatings

Electronic Component Cleaning Machine for PCB Assembly

Metallic Photo Template 41x18mm for PCB and Stencils

Vacuum Coating System UVN-74P-3M-2

Vacuum Soldering Furnace R650C

Multi-layer Structure Physical Vapor Deposition System Feba 4MI-100-G

Vacuum Soldering Furnace R320C

Vacuum Coating System UHN-74P-3M-3 for Metal Film Deposition

Vacuum Coating System for Magnetron Deposition "Oratoria 5-1

Metallic Photo Template for PCBs, 44x50mm

Emulsion Photo Template for PCB 358x126mm

About Semiconductor Manufacturing Tools

The Semiconductor Manufacturing Tools category is essential for businesses looking to enhance their production capabilities in the rapidly growing electronics sector. This category includes a range of advanced equipment critical for producing semiconductors, which are vital components for numerous electronic devices. In regions like Africa, the Middle East, and South Asia, where the demand for electronics is increasing, these tools offer a significant opportunity for growth and profit.

Our Semiconductor Production Equipment subcategory includes machinery for the epitaxial growth of semiconductor wafers, such as the Epiphase TM 200-01. This equipment is crucial for manufacturing power transistors, which are used in various electronics and industrial applications. These machines are perfect for companies involved in electronics manufacturing, educational institutions focusing on technology, and industrial firms aiming to produce high-demand electronic components.

The Thin Film Equipment subcategory provides tools necessary for applying thin films on substrates, essential for creating efficient semiconductor devices. These machines are ideal for businesses involved in the production of solar panels, displays, and LEDs, which are gaining popularity in the African market due to the increasing shift towards renewable energy sources and modern electronic devices.

Our Vacuum Brazing Furnaces are designed for high-precision joining of materials, a critical process in semiconductor manufacturing. These furnaces are crucial for companies producing high-quality electronic circuits and components, ensuring durability and performance in final products.

Typical technical characteristics of these machines include substrate handling capabilities up to 200 mm in diameter, high precision in processing, and efficient power consumption, making them suitable for medium to large-scale production needs. Industries such as electronics manufacturing, educational research, industrial equipment production, and high-tech component assembly can benefit significantly from these tools.

The relevance of these products to the African market is underscored by the increasing demand for electronic devices and renewable energy solutions. By incorporating these tools into your production line, businesses can meet local demand, reduce import dependence, and offer competitive pricing, enhancing profitability and market share.

Interestingly, the semiconductor industry in Russia has seen substantial growth, with technological advancements driving production efficiency. This trend reflects the potential for similar growth in developing markets, where local production can cater to a burgeoning demand for electronics.

For those looking to buy or import these tools, the price and operational advantages make them a worthwhile addition to any forward-thinking industrial operation. Whether you're an importer, distributor, or a business aiming to expand your product offerings, these semiconductor manufacturing tools provide a pathway to success in a competitive global market.

Frequently Asked Questions

To order products from Russia through our platform, select the product you're interested in, click the "Request Quote" button, and fill out the request form. Our managers will contact you to clarify the details and provide a commercial proposal.

We offer various payment methods, including prepayment, partial payment, irrevocable letter of credit, and other options. Payment terms are discussed individually for each deal and depend on the order volume, delivery country, and supplier requirements.

We deliver Russian products to any point in the world. Our company has well-developed logistics routes and partnership relationships with transport companies, which allows us to organize delivery as efficiently as possible.

Yes, we work with requests for supply of products that are not in our catalog. Send us a technical assignment or describe the required product, and we'll find a suitable manufacturer in Russia.